Merit Filter Corporation Sludge Dewatering System™

THE MERIT FILTER MEDIA™ ADVANTAGES Many years of developing and testing various dewatering devices for efficiency and reliability ends right here. The Merit Filter Media™ sludge dewatering system now offers the best financial alternative to both costly mechanical dewatering and obsolete, inefficient sand drying beds. Best of all, Merit Filter Media™ can be retrofitted to any existing sand drying bed simply and inexpensively. The new Merit Filter Media™ is the improved dewatering system.

LOW OPERATING COST

What could be more efficient than Merit Filter Media™? There are no mechanical parts to break down, minimal maintenance requirements and there is no power source needed other than the force of gravity. Also, there is no costly media loss as with sand drying beds. The Merit Filter Media™ system requires less polymer than other advanced systems and since operation is noiseless and produces no unwanted by-products, Merit Filter Media™ is the kindest to the environment. With the Merit Filter Media™ improved sludge dewatering system, the future of dewatering is here. But the cost advantage doesn’t end there…

LOW START-UP COST

Given that the new Merit Filter Media™ has its own built-in underdrain system and requires no technically complicated installation, the initial savings over new mechanical dewatering devices is dramatic. The Merit Filter Media™ requires only 1/6 to 1/10 of the space of outmoded, inefficient sand drying beds and Merit Filter Media™ can retrofit any size bed with installation being a snap.

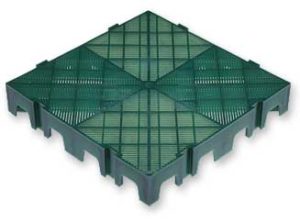

TRIANGULAR OPENINGS

Merit Filter Media™ has an inverted triangular-designed open area. The large open area means speedy dewatering of polymer treated sludge and the innovative triangular opening design defies clogging.

MODULAR DESIGN

The ingenious interlocking sections of this system allow the formation of any size sludge bed for either new construction or for retrofitting existing obsolete sand drying beds. The snap-and-lock feature eliminates the need for special tools or training. With no moving parts, there are no break downs. If a section of media ever needs replacing, the job is simple and immediate.

QUICK AND EFFORTLESS OPERATION

With its own built-in underdrain system, sludge is dried in a mere 48 to 72 hours as air circulates above and below the media, while gravity does all the work. The sludge is then easily removed with a small front-end loader, and a quick wash-down readies the system for the next cycle.

- INNOVATIVE MATERIAL

Practically indestructible - MODULAR DESIGN

Allows design of any size bed - OPENING DESIGN

Eliminates media clogging - LOW START-UP COST

Huge cost savings over other dewatering systems - LOW OPERATING COST

No power or skilled labor required to operate

Merit Filter Corporation has complete AutoCAD capabilities and can provide complete bid and approval drawings at your request.

INNOVATIVE MATERIAL

The Merit Filter Media™ sludge dewatering system is virtually indestructible and maintenance free. Constructed of high-density polyurethane, the Merit Filter Media™ can stand up to harsh chemicals and intense UV light. Only 2″ thick, this remarkable material can easily support the weight of a small front-end loader.

Because each sludge has it’s own variation in concentration, drying times may vary in accordance with the individual nature of a particular sludge. Contact Merit Filter Corporation for specific design data. Merit Filter Corporation accepts no responsibility for any operational or design data not submitted in writing directly from Merit Filter Corporation.